3rd Review

A 3rd Review ensures quality and prevents errors in documentation, saving time and resources significantly.

Conducting a thorough review establishes a robust foundation for initiating investments in prototypes or production, enhances collaboration, facilitates employee development, and ensures high production quality.

Using a review of documentation package before manufacturing offers several benefits, including:

Identifying errors or inconsistencies in the drawings early on can prevent costly rework and material wastage.

Streamlining the documentation review process accelerates project timelines, ensuring timely deliveries.

Ensuring that drawings align with project specifications enhances product quality and customer satisfaction.

Contact us today for a consultation and take the first step towards flawless manufacturing.

Drawing review include a Part analysis of ambiguities that can cause misfits during assembly, interface surfaces, constraints, assembly optimization and drawing and documentation recommendations.

Includes everything in 3rd Review – Drawing review but also includes manufacturing capability analysis in reference to part tolerance, tolerance chain calculations, and assembly mobility analysis.

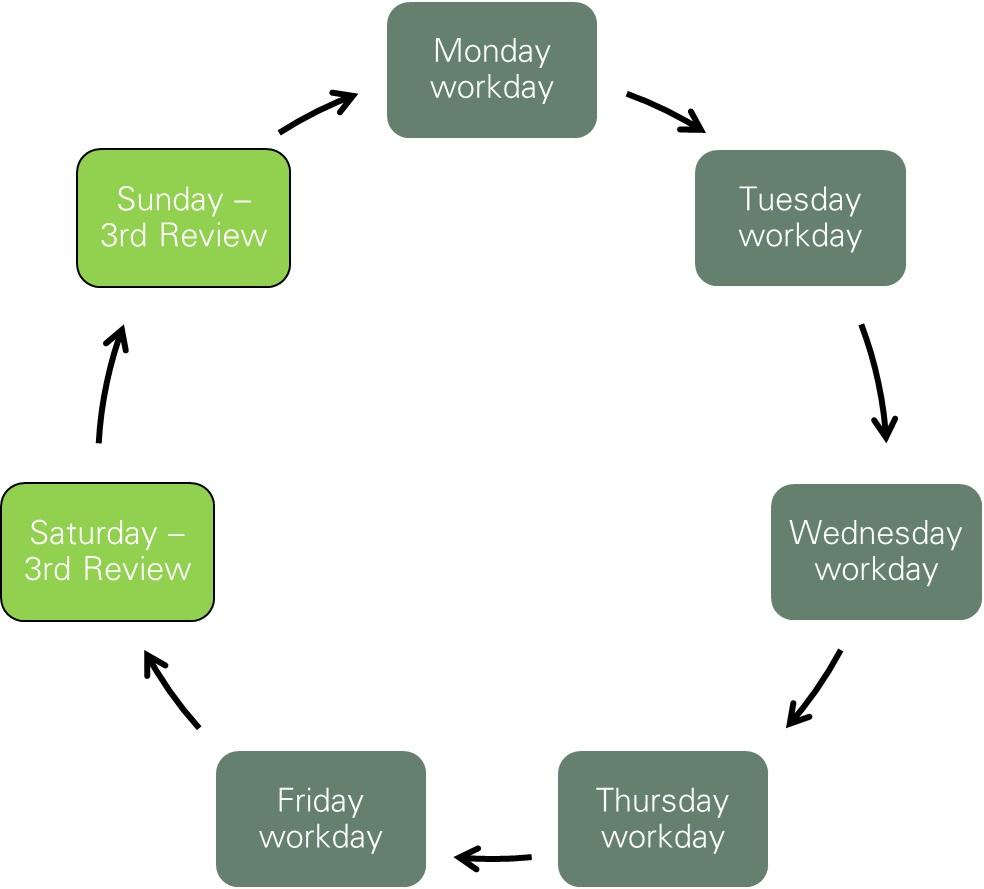

Fast-track your project development with our weekend design review service. Our team conducts in-depth reviews Saturday and Sunday, ensuring you receive a full report by Monday morning, ready for immediate action.

Mechanical Design

Achieve robust designs that ensure exceptional production quality, streamline quality control, and reduce item costs.

This is accomplished through the Robust Design method, which applies State analysis, Mobility analysis, Topology optimization, and Ambiguities analysis

Mechanical design includes requirement specification, state analysis, topology optimization, a morphological solution table, variation analysis, and ambiguities analysis.

Product Development

Achieve robust designs that ensure exceptional production quality, streamline quality control, and reduce item costs.

This is accomplished through the Robust Design method, which integrates FEM analysis, state analysis, mobility analysis, topology optimization, a morphological solution table, variation analysis, ambiguities analysis, and interface control into the design process.

A robust mechanical design includes a Design Charter, requirement specifications, state analysis, mobility analysis, topology optimization, a morphological solution table, SWAT decision-based design, variation analysis, and ambiguities analysis. This comprehensive approach ensures superior performance and reliability.